CLC Blocks

From the best of our knowledge, we are the first in Asia with a production unit capable of producing up to 20,000 CLC blocks per day.

For the past 7 years, we have dedicated ourselves to mastering CLC block production. Despite initial

challenges, our commitment to research and development never wavered. Today, we are proud to produce high-quality blocks with cutting-edge technology and innovative designs.

Our customizable molds are engineered for efficiency, allowing demolding in just 2 seconds and remolding in 5 seconds. This eliminates the need for cutting large concrete slabs into smaller pieces, saving time and resources. These molds are completely waterproof, rust-free, and built to last over 20 years, making them easy to clean and reuse.

Additionally, our foam concrete mixer is designed to mix aggregates, foam, and water while pouring

simultaneously. This groundbreaking technology enables continuous pouring, significantly reducing time and labor costs.

With our expertise, we can supply up to 20,000 blocks per day for army sectors, government projects, and housing societies. Our blocks can be customized to meet specific project requirements, offering densities between 600–800 kg/m³, compressive strengths of up to 400 to 1000 PSI, low water absorption ratios, and excellent insulation properties.

We believe in simplicity over complexity. Share your required block specifications and quantity, and we’ll provide a free sample for you to conduct the necessary tests.

Choose us for reliable, efficient, and innovative CLC block solutions tailored to your needs.

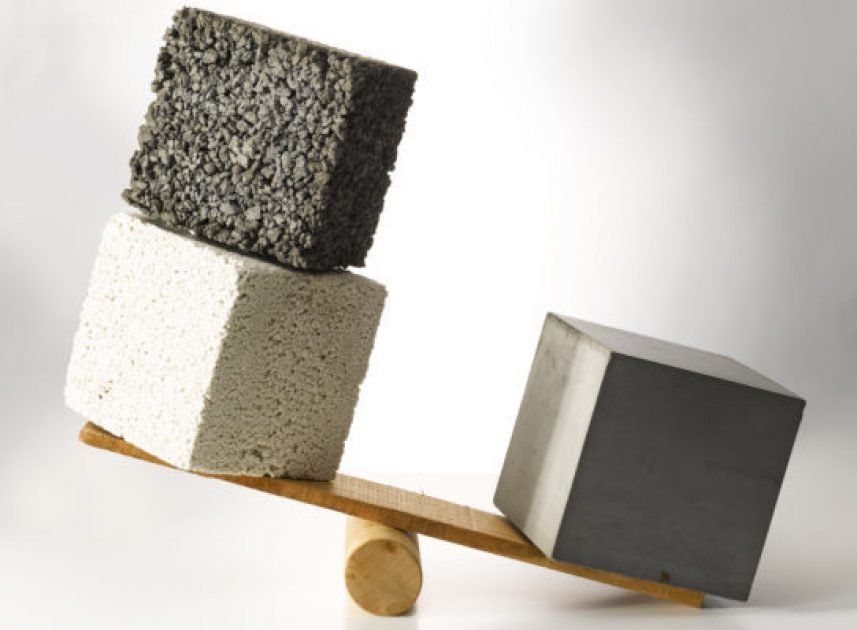

Cost Efficiency of CLC Blocks

If building designers and structural engineers plan their projects with CLC blocks in mind, they can

significantly reduce reinforcement costs in the foundations. Traditional concrete blocks weigh 60–80 kg, requiring heavily reinforced foundations to support the building’s total weight. This adds a significant investment to the construction.

On the other hand, CLC blocks are 3 to 4 times lighter than traditional blocks, drastically reducing the structural load on foundations. This lightweight property translates into substantial savings on reinforcement costs without compromising strength and durability.

And that’s not all—CLC blocks come with additional long-term benefits:

Insulation Properties:

Exceptional heatproofing and coldproofing reduce air conditioning and heating

system costs for the building’s entire lifespan.

Soundproofing:

Enhances comfort by minimizing external noise.

Details of Services

Choosing CLC blocks not only lowers construction costs upfront but also ensures energy efficiency and reduced operating costs for years to come, making them a smart, sustainable investment for any project

Environmental Benefits of CLC Blocks

Cellular Lightweight Concrete (CLC) blocks offer remarkable environmental advantages when compared to traditional concrete. The carbon footprint of concrete production is a major concern in the construction industry, with traditional concrete generating significant CO₂ emissions. It is estimated that for every 1 cubic meter of standard concrete produced, approximately 300-400 kg of CO₂ is released. In contrast, CLC blocks are produced with a considerably lower amount of raw material, reducing their overall environmental impact.

Studies have shown that CLC blocks can reduce carbon emissions by 30-50% compared to traditional concrete, depending on the mix design and production methods used. This reduction is primarily due to the lower amount of cement used in the mixture and the energy-efficient production process that doesn’t require high-temperature kilns or large amounts of energy to create the foam that gives CLC blocks their lightness.

Moreover, the thermal insulation properties of CLC blocks provide a substantial benefit in reducing the overall energy consumption of a building. The thermal conductivity of CLC is typically 0.2-0.3 W/mK, which is much lower than traditional concrete, which has a thermal conductivity of 1.0-1.5 W/mK. This makes CLC blocks a more energy-efficient building material, as they reduce the need for heating and cooling, leading to lower overall energy consumption and contributing to a reduced carbon footprint in the long run.

Another environmental benefit of CLC blocks is their ability to combat the urban heat island effect, where cities experience significantly higher temperatures than surrounding rural areas due to the high density of buildings and lack of natural cooling. Since CLC blocks provide superior insulation, they help regulate building temperatures, reducing the demand for air conditioning and minimizing the heat released into the surrounding environment.

In summary, the use of CLC blocks is a significant step toward eco-friendly construction, with reduced carbon emissions, energy efficiency, and lower environmental impact compared to traditional concrete. These blocks not only help in reducing construction-related emissions but also contribute to energy savings throughout the life of the building, aligning with global goals for sustainability and green building practices.

Applications of CLC Blocks

CLC blocks are highly versatile and can be used in a variety of practical construction applications. They are ideal for residential buildings, commercial spaces, industrial structures, and government facilities due to their lightweight nature, excellent thermal insulation, soundproofing, and fire resistance. CLC blocks are perfect for partition walls, roof insulation, flooring, and load-bearing walls, providing costeffective and eco-friendly solutions. Their reduced weight also helps in foundation savings and faster construction, while their durability and energy efficiency make them a great choice for green buildings, affordable housing projects, and infrastructure development.

Quality Assurance

At Gazillion Group of Companies, we prioritize quality in every product we deliver. Our CLC blocks

undergo rigorous testing and adhere to international standards to ensure superior performance and

durability. With state-of-the-art machinery and advanced manufacturing processes, we ensure that each block maintains consistent density, strength, and insulation properties. Our commitment to quality extends to all our services, from production to delivery, ensuring our clients receive reliable and longlasting solutions for their construction needs.

After-Sales Support

We believe in building lasting relationships with our clients, which is why we offer comprehensive aftersale services. From installation support to product maintenance, our team is always available to ensure your complete satisfaction. We provide timely assistance with any technical queries and are committed to addressing any issues promptly, ensuring that your projects run smoothly long after the purchase. Our goal is to offer ongoing support and ensure the continued performance and reliability of our products.

We are confident that we can help you achieve your project goals. We look forward to a positive and successful collaboration with you. Please send us your required specifications, and we’ll provide you with a detailed quote and discuss the next steps to move forward.