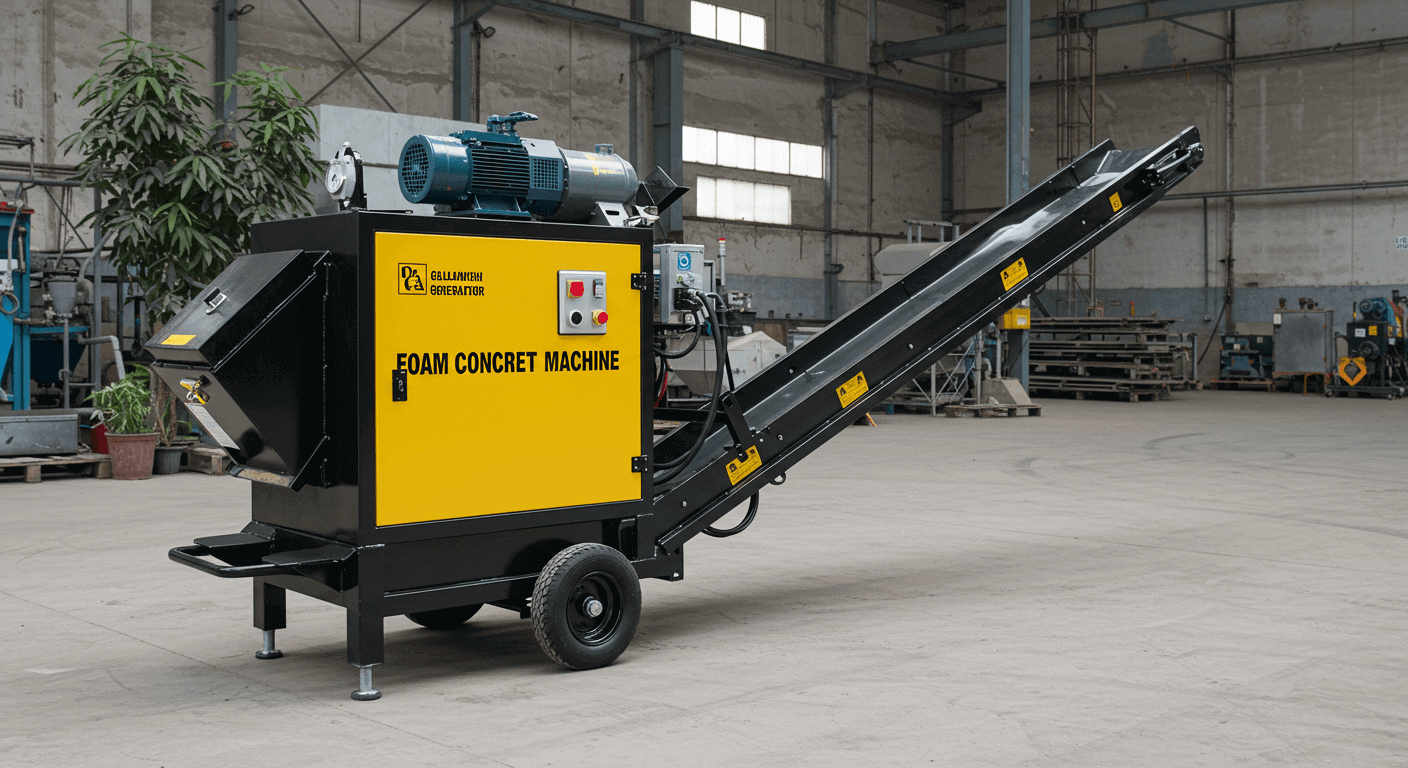

Cellular lightweight foam concrete machinery

With years of research and development, we can produce up to 20,000 blocks per day while maintaining significantly low production costs. We deal in all kinds of cellular lightweight foam concrete machinery and deliver complete technology to the customers across Asia.

Mixers

There are two types of mixers: traditional mixers and the one which is ours.

What’s Special About Our Mixer?

It can continually intake raw materials like fly ash, pumice stone, rice husk, sand, cement, or other chosen aggregates and chemicals, while at the same time continually pouring the concrete into your desired destination through our pump.

Concrete Pump

Steam Chamber & Industrial Dryers For Curing The CLC Blocks

We also offer advanced steam chambers and industrial dryers designed to efficiently cure and dry CLC blocks, ensuring consistent quality and faster production times. Normal curing typically takes 18 days, but with our system, it only takes 3 to 4 days, significantly speeding up the production process while maintaining the integrity and strength of the blocks without the risk of cracking or deforming.

CLC Block Molds

Our customizable molds are meticulously designed for maximum efficiency, featuring a rapid demolding time of just 2 seconds and remolding in 5 seconds. This innovative design eliminates the need for cutting large concrete slabs into smaller pieces, streamlining the production process, saving valuable time, and reducing material waste. These molds are made from high-quality, durable materials, ensuring they are completely waterproof, rust-resistant, and can withstand over 20 years of continuous use. Additionally, they are designed for easy cleaning, allowing for effortless reusability, and ensuring long-term reliability and cost-effectiveness in your production line.

Types of Foam Concrete

Our expertise divides foam concrete into three distinct categories, tailored to meet the needs of various applications:

Foam Concrete

The foam concrete is the one in which we inject the foam through our foam generator using foaming

agents and other basic aggregates (lightweight or not), and we call it foam concrete.

This type of concrete is ideal for areas requiring high insulation or drastically reducing the weight of

concrete by adding foam.

Density: 400–1800 kg/m³.

Lightweight Concrete

Designed with lightweight aggregates, without adding the foam.

It is used where insulation is not the first priority but load-bearing characteristics and high PSI are

required.

By choosing the right materials, insulation properties can also be managed.

Density: 600–1800 kg/m³.

Lightweight Foam Concrete

This concrete is ideal for almost every application.

It cautiously uses raw materials and foam through a foam generator, providing the best combination of characteristics.

Formulations can be customized to meet specific needs, including controlled thermal conductivity,

density, water absorption ratio, and PSI.

Moving Back to Machinery

We have designed our machinery with these different types of concrete in mind.

Built-in foam generators produce high-quality foam in good quantity.

The system automatically pours water into the mixer and injects the required foam into the concrete.

Aggregates are automatically delivered to the mixer, making the whole process 90% automatic.

Mixer sizes and the technology you require (manual or automatic) are available on demand and highly

customizable.

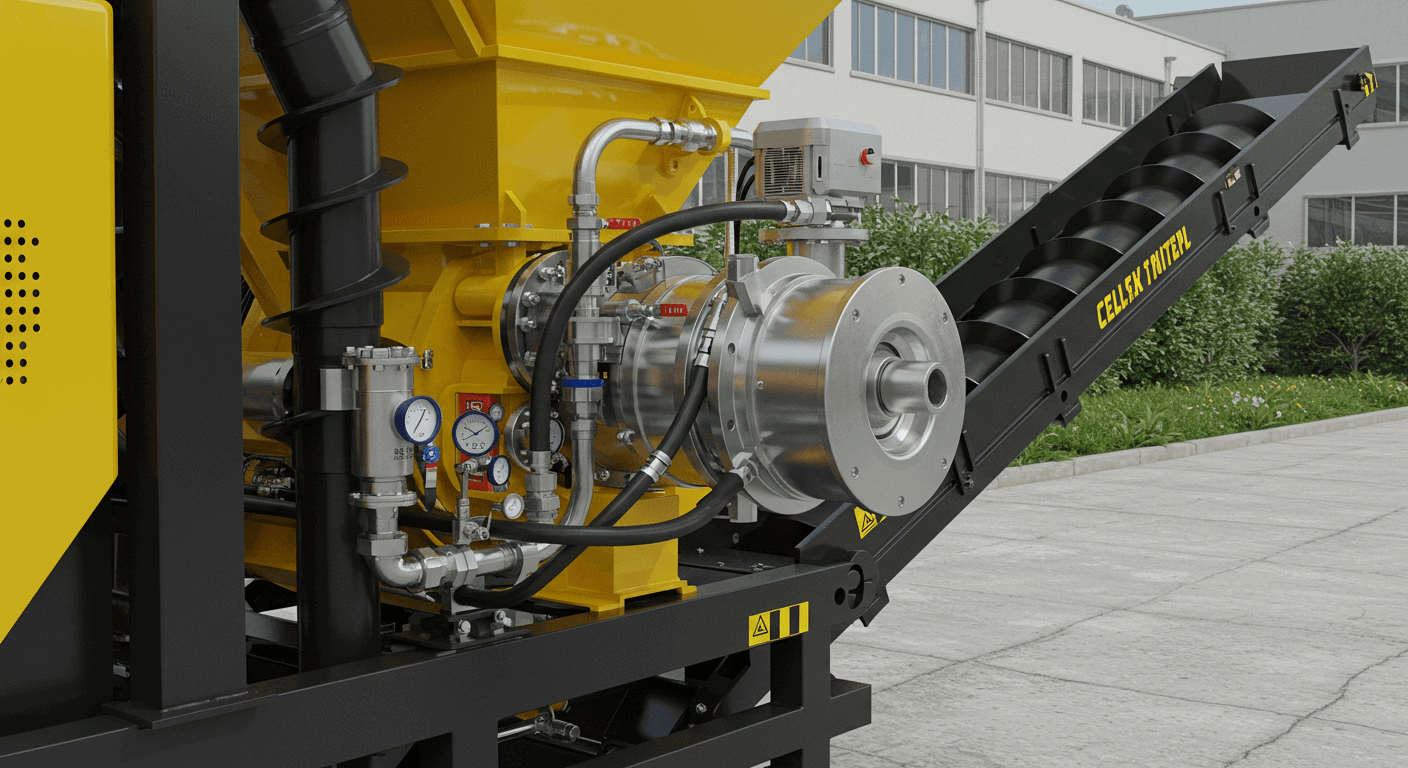

We understand the sensitivity of foam concrete; therefore, we design a pump that can continually pour the concrete without disturbing the foam and bubbles in the concrete.

Foam Generators

Our foam generators are highly productive, consuming less water while producing a larger quantity of foam. The quality of foam depends on the foaming agent being used. Our foam generators can be operated automatically or manually with a timer setting. We can also adjust the foam density to suit your needs. For optimal performance, we recommend using a separate compressor with our standard foam generator, which provides a continuous airflow of 3 to 4 bar.

For those on a limited budget or testing the waters, foam generators are also available. With just a

simple drill paddle and a plastic drum, you can start small projects like roofing or subflooring for

insulation.

Just go green! And contribute to building an eco-friendly future.

Tell us your production needs, and we will provide a tailored quote with the best prices, recommended mixer sizes, and all necessary technical details to meet your requirements.